Fiberglass Mesh & Machine

A pioneer in fiberglass mesh manufacturing and supply, Meiya started development of fibre glass mesh plant in 1999 and currently delivers fiberglass mesh / screen / netting and machinery to more than 20 countries in the world. Meiya also helps with onsite training of technical staff and installation of machinery.

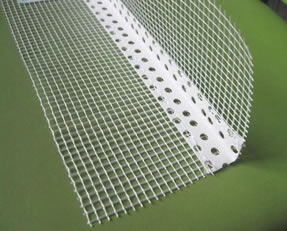

Fiberglass Mesh as Building Materials, Used as EIFS Mesh, or Stucco Mesh Wings for Plastering Angle Bead

The mesh fabric is woven with alkali-free glass fiber yarn, coated by alkali-resistant polymer emulsion.

Fiberglass mesh is  a high strength engineering fabric widely used in wall construction reinforcement, external wall heat insulation, and waterproofing plastering base.

It is also used to reinforce cement, plastic, bitumen, plaster, marble, mosaic and other building materials.

a high strength engineering fabric widely used in wall construction reinforcement, external wall heat insulation, and waterproofing plastering base.

It is also used to reinforce cement, plastic, bitumen, plaster, marble, mosaic and other building materials.

Feature:

1) Mesh Size: from 4 x 4mm to 10 x 10mm

2) Density: from 60g/m2 to 300g/m2

3) Width: from 0.2m to 2.5m, usually 1m

4) Roll length: 20m to 500m, usually 50m

5) Color: white, orange, blue any colors available

6) Packing: Inner packing: Shrink film put on the Carton; Outer packing: Pallet

7) Logo printed on the mesh: available

8) Hard or soft mesh are both: available

Adhesive Fiberglass Tapes

Fiberglass mesh in tape form is mainly used for reparing joints or cracks between walls.

Specifications: 8 × 8 Mesh / inch, 9 × 9Mesh / inch,or 55-85 g / m2.

Width: 25-1000 mm

Width: 25-1000 mm

Length: 10-153 m

Color: usually white.

Installation of Plaster Mesh Tapes:

1. The wall shall be clean and dry.

2. Adhere the tapes and press it firmly against the cracks.

3. Confirm the gap has been covered by the joint tape, and then cut off the excessed tape, then put on mortar.

4. Let it dry by air. Then polish it lighty.

5. Fill in paint to make a smooth surface.

6. Remove the tape going out. Be sure all the cracks have been properly repaired. Decorate around the joints with composite materials, to make it clean as new.

Fiberglass Nets For Window/ Insect/ Shading Screen / Door Curtains:

Glass fiber filaments coated weaving netting. Coated by an ethylene or latex polymer coating from heating process. Fiberglass netting is resistant to weathering, corrosion-resistant, easy to clean. Supplying types can be mesh rolls or plisse mesh in pleated mesh pieces cut to size for retractable window frames.

Features:

Long life: Anti-aging, anti-cold, anti-heat, anti-drying and moisture resistant, flame retardant, anti-moisture, anti-static. Light transmission is good, no deformation, anti-ultraviolet, high tensile strength, long life and other advantages.

Can be installed directly on the window frame, wood, steel, aluminum, plastic doors and windows.

No toxic elements, no taste

Windows screen gauze use glass fiber yarn can prevent fire.

Good ventilation.

Good light transmission, invisible effects are particularly good.

Against UV, automatic filtering light, protection of family health.

Common Product Specifications

Mesh: 14x14 mesh, 16x16 mesh, 18x16 mesh.

Width: 0.6-2.7 meters.

Color: white, black, gray, gray (gray weft diameter white).

Weight: about 120 grams / square meter.

Uses: For window and door screening of high-grade office buildings, residential and various buildings, livestock farms, orchards, etc. To ventilate and to prevent insects, mosquitoes, bugs, or even pets.

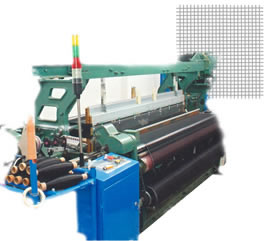

Fiberglass Mesh Weaving Machine Designed and Developed For Export

Fiberglasses mesh machine has high production capacity, can be used to produce good quality fiberglass mesh and window screen fabrics. The machine is designed controlled by computer operation automatically.

The main parameter:

Outside size: Length:2800mm width:1800mm heigth:2200mm

The maximal width of weaving: 2300mm

The maxiaml mesh: 60mesh( there is 60 open aeras each inch)

The maximal diameter of weaving: 2.0mm

The minimal diameter of weaving: 0.02mm

Power: 3KW/set 0.12 KW/set

Output: In theory: 1200m/24 hours

The best for the machine: 800m/24hours

Gross weight: 2.8T

Fiberglass Yarn Drawing Machine

Fiberglass Yarn Drawing Machine Temperature Control Device

Temperature Control Device Yarn Winding Machine

Yarn Winding Machine Mesh Weaving Machine

Mesh Weaving Machine